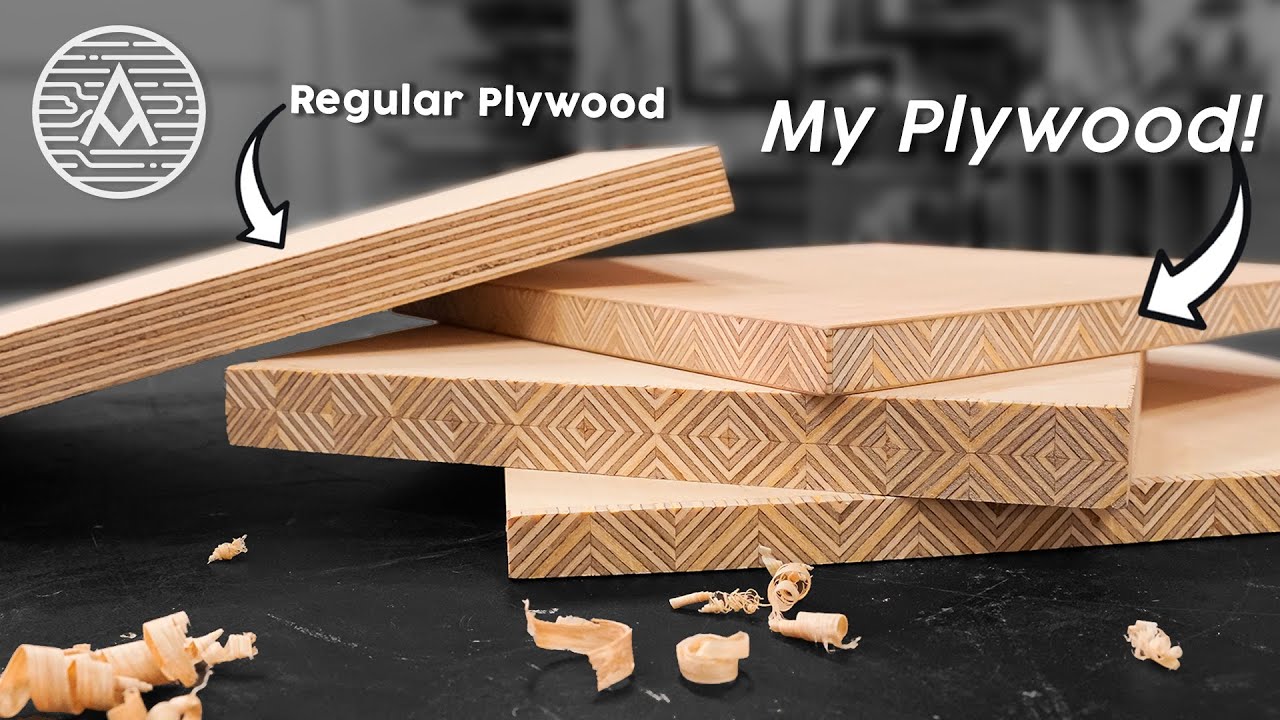

so i make quite a bit of plywood furniture

in my shop and whenever i make a furniture piece i have to think about whether

i want the exposed plywood edge or to cover it up with edge banding and it got me

wondering if there's actually a third option that's what i'm gonna be working on this

week to see if i can make a decorative edge make it look like exposed plywood but a

little bit fancier so let's give it a shot those of you familiar with the channel will

know that i make a whole bunch of patterned plywood i take the edge grain of plywood and i

glue it up into various different patterns and that's what i'm going to be starting with

today i'm i'm working on a chevron pattern as my first test that involves just cutting a

whole bunch of strips out of baltic birch plywood the chevron pattern is going to be on a 45 degree

angle and so i like to push all of my strips onto that 45 angle strike a line with a speed square

and that way i just have an indication this isn't doesn't have to be super precise it just saves on

material those ends are going to get cut off and you might as well maximize the

amount of yield out of this blank so i'm gluing up the face side of the plywood

because i want the edge grain to be exposed so i've tipped all of them forward i'm going to lay

out all of my glue with a roller and then tip them back onto themselves being mindful of that

45 degree angle again then i'll clamp them up well i have to say i was a little worried about

the amount of squeeze out on this blank i really didn't get a lot i like to see a little bit more

because i'm going to be cutting this into tiny pieces i probably should have put more glue on but

we'll see how it goes when i cut it into strips the first cut i'm gonna make on this blank is with

my track saw and that same speed square again if it's not perfectly 45 degrees it doesn't really

matter uh the the pattern will still match up you can actually go at any angle that you want i've

seen people do them at 60 degrees and they look really cool too this is just what i chose and then

i can start passing the blank through the table saw i'm cutting a half an inch wide and so far

they're holding together which is which is good with all my strips cut i can

lay them out on my clamps and i just flip over every other strip

and that forms the chevron pattern if you want these to match up really well

just make sure that the ends are aligned so those kind of pointy bits at either end if

they line up the pattern will line up great when i was going to do the glue up i realized

that i didn't have quite enough room inside my clamps i thought for a second about setting them

to the side but i fortunately have a set of four foot long shore foot clamps i get questions about

these clamps a lot because i use them a ton in my shop i've had them for a number of years they're

made by rockler and they are they're great i i had the harbor freight ones before and those were

a good uh temporary solution but they started to bend and warp these ones have held up awesome i'll

post a link down below to where you can find them i had much better squeeze out on this go-round

that's about what i want is just a little bit above and a little bit below um so i feel pretty

confident i have noticed that when you glue up that the second glue up it absorbs a lot more

glue so a lot of times i'll do i'll do two coats i squared off one edge and then ripped a strip

i'm not gonna rip the whole blank apart at this point because i really don't know how this

is gonna go this is all just an experiment so uh this is the first one and

it looks pretty good it's about an inch tall and half an inch wide a little bit

a little bit wider than the plywood that i want to line i'm basically going to resaw

this from here so i'm using my bandsaw fence set at 3 16 of an inch and i'm going to see how

it goes see if they fall apart or hold together well i know that may look like a little bit of a

fail but it's actually pretty good that's better results than i was expecting i was worried that

i didn't have enough glue in that initial glue up and there's definitely some that are

breaking but most of them are holding these are actually pretty fixable i can use just

some ca glue and glue them back together but i'd say i'm really happy this is uh this is really

good i did notice a bit of chatter right here i might make these a little wider so that when

i sand them down i can get rid of that chatter but yeah this is looking pretty good i'm going to

experiment with making them a bit thinner see what happens these are at 3 16 and i'm going to try and

do them at an eighth inch they may just fall apart but it's worth experimenting well while i've got

the blank to work with i ripped the second strip a little bit wider than the first one and then

i i made it a little bit thinner so it should if i have got that chattered edge i should have

room to sand it out and this way i can i can see how thin i can go i don't think i want to go much

thinner than an eighth inch because i don't think it's going to glue up very well but an eighth

inch would be perfect if i could pull it off oh oops all right well these work well i completely

messed up that first strip so i cut another one and i wanted to get a full test to see how

many strips i could get out of a single blank well that's pretty fantastic right there that is

uh six pieces out of this one piece right here this is an inch inch thick so that's great i

even think that uh i can get rid of some of this chatter on the edge by working on my

zero clearance on the bandsaw but there's just so much potential here i'm gonna test it

out on a piece of plywood but i also realized that if you flip it back and forth you

can get the diamond pattern which is like that this would look really cool as edge

banding in and of itself you could just use the diamond pattern like that but

oh man there's so much potential meanwhile i decided to test out some zero

clearance options i think what's causing the fuzzy edge is the fact that my zero clearance

insert my band bandsaw is pretty used up and i'm trying this hack that has worked for

me in the past where i put a thick piece of tape right up against the blade and it's sort

of like an improvised zero clearance insert unfortunately this didn't seem to

do much at all there were still some pretty noticeable fuzzy edges so on to plan b i found a piece of plexiglass lying

around in a scrap bucket and i thought this might work a little bit better i think that's about as good as i'm

gonna do i i can't seem to get the fuzzy little bits to go away completely

but they're a little better with the with the plexiglass so i'm gonna run with

that and just batch a whole bunch out so well i am thrilled with how that looks i was

a little worried that the eighth inch would be super thin and would get wobbly uh

wouldn't clamp up nearly as well but i haven't seen any of that there's no voids along

this this edge and um yeah it just looks great so this gets me excited i've got a couple other

ideas of things that i can do the main one is to do the the diamond pattern on the

edge as opposed to just the chevron and i think that's gonna look really cool one

thing i'm gonna do is bump it up to three quarters of an inch so that you can see

more of that pattern so let's try that i still have that piece that i messed up earlier

and it turns out that that is the perfect width to to make uh two strips that equal

three quarters of an inch so i just went ahead and ripped

that piece down to size since i'm going to have to face these pieces

into each other i wanted to make sure that they were very flat and that they didn't have any

fuzzies so so i sanded them up on my sanding board they are very fragile so i

have to be pretty careful it i had enough to wrap around this

piece of plywood if i cut all of them in half so i measured them

out and cut them with a chisel so and i mean it just looks awesome it looks so

good i'm i'm uh very pleasantly surprised by this and i can just think of a million projects

that i can use this on in the future one thing that i know that people are going to ask

about is this is this exposed edge you've got the the plywood edge here and i think

i've got a solution for that too veneer so i'm going to try veneering a panel

i've seen people do this before i think john peters has done this on his channel where he'll

apply the edge banding and then veneer over the top of the edge banding it's a really smart way to

get a seamless look so i'm going to give it a go i'm going to be using contact cement

to attach the veneer to the wood it works really well you basically just

spread it on wait for it to dry and then stick the two pieces together it is incredibly

toxic though so make sure you wear a respirator once the contact adhesive has had about 15 to

20 minutes to dry it's good to go and and then i can apply the veneer gonna be really careful

with this the instant it's stuck it's stuck permanently so i just kind of roll it out and then

use a scrap piece of plywood to burnish the edge i've rounded over the front edge of the plywood so it doesn't scrape into it but it

does apply quite a bit of force well the veneering works great

and it's hard to be more pleased about that um yeah this has got so much potential

i'm actually i've actually already started a piece of furniture made with this stuff because i was

so excited about it so that will be next week's video make sure you're subscribed big thank you to

patreon patreon supporters you guys are the best i really appreciate it if you want to join the

patreon there's a link over here and if you want to see more pattern plywood videos i've got a full

playlist over here i'll catch you on the next one you