the new on hmmm hi I gotta really neat little project to do

today this is really simple it you can get it done in

about an hour I'll use a drill press I read about this in the September 2007 issue of American Wwoodworker and since that a lot of people in writing

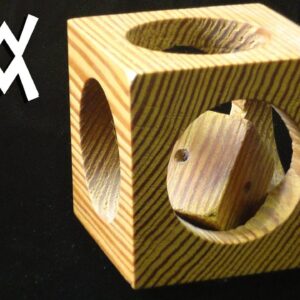

and in coming up with enhancement but this is the basic cube within a cube and its sort of a puzzle it looks

like there's a cube in there any wonder how to get in there because

there's no way for it to come out, so it's just I don't know what it is but ta lot of fun with so there is a closer look at what this is is just a solid chunk of wood I think

this is 3 inches by 3 inches square and inside is a floating cube of course there is no way to get that outta

there and i dont know its a kind of a conversation piece and if you have it sitting around people will pick it up and can of wonder how you did it! one

of the things to do about this is get solid chunk of wood you really dont want a laminated wood to make it otherwise people will see those lines together and assume that well you just put together and glued all up part at the interesting parts to use

solid block away so got a piece of wood square and we

have started okay the first thing you want to do is find the centerpoint on just one of the sides and gotta be really precise

about it cuz you really want to get as close to that center as you can and just draw a line like so now i got the center spot next you wanna put just a little X in one corner of each side so when you put it

into the drill press you can make sure you were positioned the exact

same location each time next you wanna head

over to your drill press set the speed of your drill press at the

slowest speed install a forstner bit in this case

I'm using a two-inch forstner bit to make the whole on 3 inch block

but depending on size of your wood you can use whatever you want, set up a stop block on a fence if you dont have a fence on your drill press you just clamp down a board anything

all work the stop block will never change

throughout the whole procedure so when you get back clampdown you find the exact Centerpoint when they drop the drill press down it will go right to the center so that's the

basic setup so this first cut just kind fo eye balling it about a 67 looks like it there one thing I'd to be aware his I set my "X" in this location up so every time I cut a piece I'm gonna make

sure the X is on the left side it's kinda arbitrary go anyplace you want but you just want

to make sure that you have that same position each time you know just in case your

block isn't exactly square take a square and draw a line from one

of these diagonal lines that you made previously to where it intersect that circle so well like that underline that's going to mean indicator of how deep to make the first

cut now at that line drawn I can use that as a guide to set up my

drill press and you can just line it up visually

along the side there and you want your bit to come down about 0,16 of an inch higher than that line you don't wanna go any deeper than that

you know for fear that it would cut all the way through the

cube so enter our way down from there setup a stop on your press where it

stopped a sixteenth inch above-the-line now that I've got that

depth set I can make my first cut and I'm

gonna position the X again in that same left position and you want to start with the end grain

because it's tougther to get through and it could chip out if you do that

last so just start in all down way around each side all making sure

that the X is in the same location also make sure you look

clean out any shaving might be in this area so that sit

proper well the face grain is definitely a lot

easier to get through than the end grain and with that final face cut you can

start to see the cube inside so now it's just a matter of

getting closer and closer to where it is about ready to release and

with all six bases cut over, i lower at the bit about a 0.32 of an inch and I'll

just inch my way around each side and if you

can see that it's a almost ready to release so I'll take it down about a 30 second

half an inch the next time you just want to be

careful you don't wanna go all the way through or this'll just

breakout splinter now that I've got that down to right about it is ready to release from the word I'm just gonna take a

sharp knife and cutaway the remainder try to go with the grain when you make

this cut and you feel it release and with final cut the cube is released and there's no real

easy way of sanding it all down sand paper combination now wraps for eventually you will get it done there you go the only other thing left

to do would be to finish it and if a can find my original this one that i a made and I used and oil finish on this I I just rube oil all over it I it's really not practical to put polyurethane lacquer or anything else on their I would also

recommend not painting it because its I think part of

the charm others to do you see the grain would painted it it was just cover that

up and loose some of the mistery on how it was made so in a way that I can make a cube whitin a cube, and you can get it done in a half hour I hope you give it a shot if you do so, send my an email or put your own video it would fun to see other versions of it I've seen some that have cube winthin a cube whitin a cube and a haven´t been bold enough to try that one so anyways good lucky and thanks

for watching