<<Jibberish>>…is sponsored by MicroJig. Maker of the Grr-ripper Work safer, work smarter. Why is a raven like a writing desk? Of course this is one of the greatest unanswered

riddles of all time, put forth by The Mad Hatter, and of course, Lewis Carroll. My personal favorite answer to that riddle

is, "Because there is a B in both and an N in

neither." I can't wait to see how Ivan translates

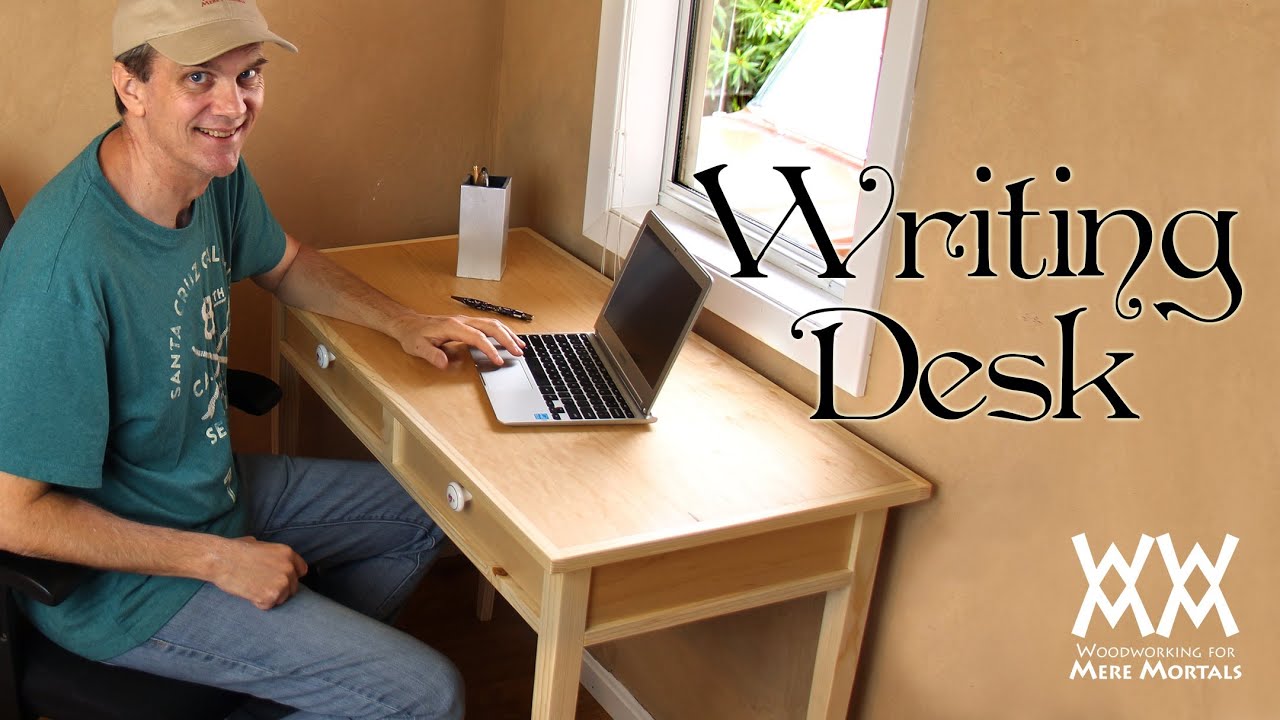

that into the Spanish captions! Speaking of ravens, I made a writing desk.

Mine is made out of maple and pine and it's got two drawers for storing stuff. There's something so quaint and sophisticated

about a writing desk. I'm gluing together these 1x4s to make the

legs. With those dry, I can cut them down into 1

½" legs. And I'm cutting all the legs to 29 ½"

long. The way I've made tapered cuts for legs

in the past is to make up a jig like this one. These are pretty simple to make, It's just a plywood board with another plywood

board mounted at an angle,

So I would put my work piece in like this against this cleat at the bottom and lock

it into place. To make the cut, I would just run this along

my fence. But I gotta tell you, having MicroJig as a

sponsor is pretty cool because they sent me one of their MicroDial

tapering jigs, which, when I first saw it, looked overly

complicated and very intimidating. In reality it's very simple to use and is

infinitely adjustable. And rather than having to draw that line out, I can set this rise over run scale.

And just like my homemade jig, this has a

little cleat down here that grabs your work piece and pushes it through your saw. To hold it in place, I will use these Grr-rippers. I can make the first two cuts with this setup. To make the second cut, I'll turn it on

its side and re-adjust my Grr-rippers. For the next two sides, I need to double the

angle to compensate for that cut. So that gives me tapered legs that are an

inch and a half square at the top, drops down five inches and then the taper

begins and goes all the way down to ¾" square. I find that the shorter pieces are a lot easier

and more accurate to cut on my crosscut sled. This is one of the rare times that I was able

to pre-cut most of the pieces for this project. The only ones I haven't cut are the drawers

and the drawer fronts, which I will cut to size once it's assembled.

For the plywood back and side panels, I'm going to drill pocket holes on all sides.

I'm going to glue and screw these plywood

panels to the centers of these rails. I'm just going to line it up visually into

the center. I'll hold it in place with a clamp while

I put the screws in. Now I can assemble the sides. Since my taper doesn't start until 5"

down, I need to clamp this top part flat. I'll turn it around and do the same thing

on the other side. I'll attach the back panel the same way. Clamping this front rail on will help keep

it square while I put the screws in. The center divider is a little bit different.

It goes together like this. It's got a little overhang on this side, and this block just lines up like that. To line up this middle divider, I've cut

two spacers that I can use to center it. This front rail goes on this little block

and screws into the two sides.

I'm driving a single screw into this center

post. To use these side-mount slides, I need to

mount it to this plywood piece which sets in a little from the legs, so I

need to add a half inch spacer. I've made this ¾" spacer that's going

to just sit on that ledge. This half inch spacer I've put glue on and

I'm going to stick it on and tack it to the side. Now I can take this spacer out and use it

on the next one. Now I'll set that spacer on this one, and

attach this spacer.

This one's a little longer since there's

no rear post. I'm using ½" plywood for the sides of

the drawers. I'm cutting rabbet joints on the ends of

the front and the back of each of the drawer pieces. And I'll cut a ¼" rabbet along the bottom

of all 8 of the drawer sides. I'm setting up these drawers so that I can

cut the bottoms to fit. To install the drawer slides, I'll put these

lower spacers in again. That ¾" plywood leave a little ledge that

I can set the slide on and get it into position. I'm using those holes that are kind of elongated

so that I can I can move this if I need to adjust it. Now I can take that spacer out.

To install the drawers I'm going to shim

them up ¼" using ¼" plywood. And I can drop this in like that. Now I can pull it out a little bit more and

get the next hole. I'm adding some iron-on edge banding to

the drawer fronts that I cut out of plywood. Since the drawers are ¼" higher than the

frame, I've got an ⅛" sheet of plywood that

I'm going to use to shim up the fronts. And once I get that centered about how I like

it, I'll clamp it down. And I'll secure it with a couple of 1"

screws. I've take the drawers out because I want

to attach the top and I just realized a mistake I made. I cut these pocket holes so that I could screw

the top on from underneath.

As you can see, these pocket holes are covered up by the drawers slides. When I was designing this, I thought I was

going to be using bottom-mount drawer slides So now I'm going to glue the top down. I'm making edge banding for the top cutting

¾" x ¾" strips. I'm going to use spray lacquer for the legs

and the underside parts. That will be a lot easier. And for the top, I'm going to use brushing

lacquer. I've you would like to make your own writing

desk, check down in the description for a free set

of plans. If this is your first time here to Woodworking

for Mere Mortals, welcome!! And you should know that I post brand new

videos every Friday on this channel and I'd love to have you subscribe. And I'd like to invite all of you to check

out and subscribe to my other channel, Mere Minutes, where I post two videos a week. And finally, if you have an answer to the

eternal question, "Why is a raven like a writing desk?" Leave it down in the comments! It will be fun to read all of those.

Thanks everybody, I'll see you next Friday..