I wanted to call this video: "guitar making for weekend woodworkers and other guitar enthusiasts with no woodworking experience who always had a dream of

building their own guitar but never had a clue where to start" But that would have been a

very long and confusing title Anyway now I hope you get the idea. Hi I'm an amateur woodworker from Belgium and I'm here to tell you everything I

think I know about making a guitar at home Before we start you should know that

I'm not a professional guitar maker, I don't sell guitars I just make them for fun and always

try to learn something along the way. I started woodworking as a

hobbyist three years ago, and I only picked up on guitar

making about a year ago, and in that time I've built eight instruments, six of which are featured on my youtube channel.

I've been a Brian May fan for most of my

life, and building a guitar on my own, like he did with the Red special,

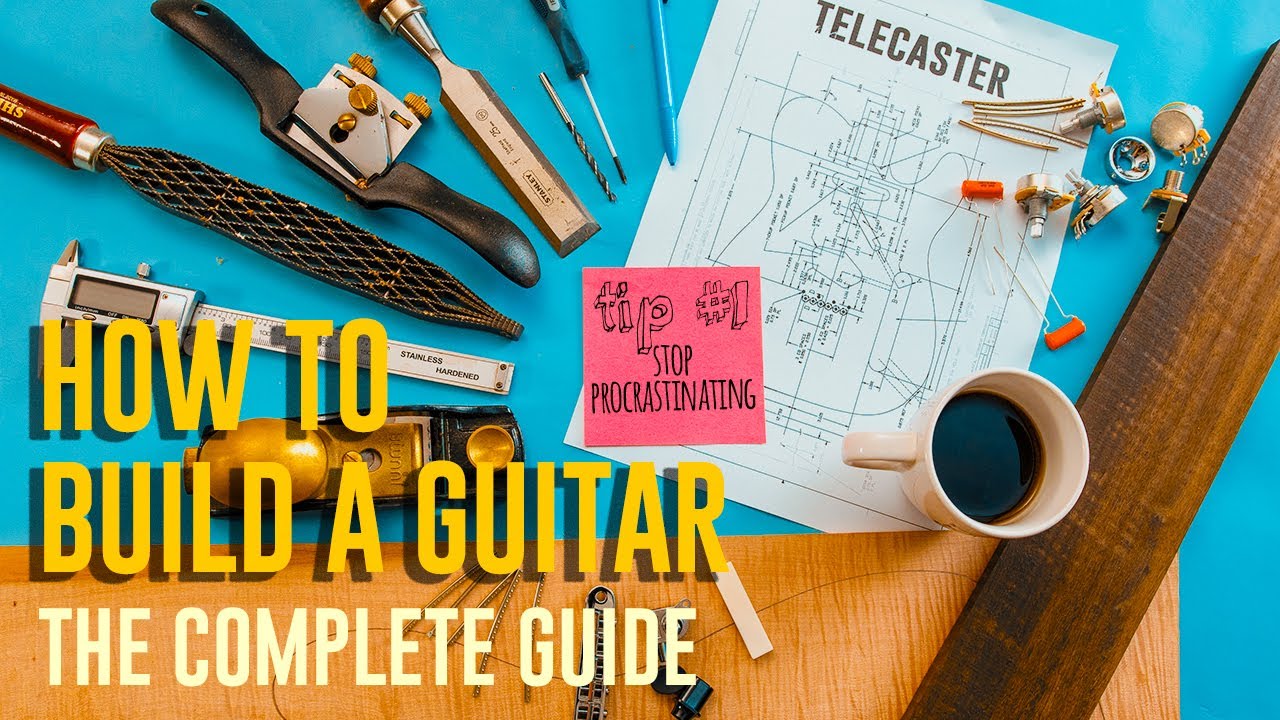

has been a long time dream. When I was done with my first build, as I said, it was 15 months ago, I realized that in this day and age, with a bit of documentation, a bit of

practice, the right tools, and a lot of coffee, anyone should be able to make

a half decent guitar at home. In the end, you are probably

not gonna sell that first guitar and it might have some flaws here and there. But it's gonna be your first DIY guitar. One that you've built with your own hands, and that you can play after a long day at work, or simply watch with pride, whenever you're feeling like an empty

shell, crushed by the burden of adulthood. If you think you're not good with your

hands then this will give you hope, … …three years ago, I didn't

know how to use a chisel, or any of the tools I'm about to show you.

But i was born in 1986, which

technically makes me a millennial. And do you know what millennials are good at ? The answer is: learning bizarre new skills, out of boredom, on their own,

just by watching youtube videos, in the comfort of their couch. And I've been doing a lot of that lately. Today I'm gonna share my findings with you. In the first video of this two part series, I'm going to talk about the

tools needed for a guitar build. What they do what you should

buy and what is optional. Then i'm also gonna talk about the hardware,

wood options, the plans, timber dimensions, as well as more general

consideration for a first time build. By the end of this video, hopefully,

you will be ready for the second part, which will be a step-by-step

guide through the build itself The guitar we're gonna build

today is a Telecaster copy.

Like it or not, it's an iconic

guitar and one that I love. And I think it's the ideal guitar

for our first project and there's a host of reasons why. The main one being that it's the absolute

simplest guitar design I can think of, but more on that later. This tutorial is based off of a guitar

that I built using only hand tools … and one hand. But I make the vast majority of my guitars

using both hand tools and power tools … and also both hands If you are on a budget or if you don't want to invest your money time and

space in expensive machines I think the hand tool approach would be the best In the description below you will find a list with

the names and brands of the exact tools that I use If you start from nothing the list may seem

daunting at first but with the exception of a couple of items, most of the tools are

very affordable and generally speaking they are valuable woodworking tools.

So in the end, even for a hobbyist, I think it's a good investment Well

at least that's what I tell my family.

Now let's kick off with the hand tools My main saw is a double edged Japanese pull saw It allows me to crosscut and

rip cut using the same saw I highly recommend this type of saw, especially for beginners. It's very easy to use and it's a

great general woodworking tool. But you can use any saw you want

as long as it cuts through wood In addition to the first saw which can only cut

straight, you will also need some kind of fretsaw or coping saw, to cut tight curves

around the body and headstock.

You will need a rasp to remove a lot

of wood rapidly with some control I use a shinto rasp it's cheap, it's very

efficient and you can use one side for rough work and the other side for more detailed jobs. You will need at least one clamp but

I usually use two, whatever I'm doing. The first one holds the piece down, and the second one keeps the piece

from rotating around the first one. I hope it makes sense. In addition to regular clamps you're going

to need a couple of long reach clamps, to glue the body blank together. You will need at least a 6mm chisel as it is exactly the width

of the truss rod channel. I used the 15mm chisel for the rest

of the build as an all-around chisel.

By the way, those are cheap chisels, they cost 10 euros a piece and they're just extremely sharp. You will need some kind of

mallet to strike the chisel in. Anything will work as long as it's heavy enough. You will need a hand drill to drill holes

for the strings to go through the body. But also to attach a lot

of hardware to the guitar. If you want to make the guitar

entirely by hand like I did a hand drill is also very good at

hogging out a lot of wood very fast. For this build you will need some

wood drill bits of various sizes and at least one Forstner bit. For the jack plate hole you will need a 22 mm bit, it can be your Forstner bit,

a spade bit or an Auger bit. The spokeshave is optional. It does make shaping the neck

look kind of cool on camera, but you can do it with a rasp.

I put hand planes in the optional ones because you don't strictly need one. But if you've seen my videos, then you know that i use hand planes all the time, even for things that could have

been done with something else. I don't know i just like hand planes. If you plan on doing any kind

of woodworking in the future, do yourself a favor and just get one. It's a great tool and it forces you

to understand how wood grain works.

I'd suggest the number 5 plane also known

as the jack plane, as an all-around plane. You will need a metal file for the fretwork, which includes making the fret

ends flush with the fretboard, spot leveling, crowning,

and rounding the fret ends. I also use metal files for

very delicate works on woods. If you can only have one, get a straight

one with the fine grain and the safe edge. You will need one of those to know

precisely where to cut and drill. A marking knife is more precise than a

pencil and a box cutter just won't do. Because you only want one

bevel on the cutting edge, so that you can butt up the

non-beveled side against the ruler. You will be more consistent and will save a lot of time by using either one of those

marking gauges But it's optional. If you want to get one, try

to get the one with the wheel. It's great with oddly shaped pieces like a guitar.

You'll need a thickness caliper, a square,

a long metal ruler, and a tape measurer. I soldered my first harness

with my wife's wood burning pen. It worked but it was a terrible idea, because it was way too hot

and there was no temperature control Just buy a soldering station

and some basic equipment, it doesn't cost much and it will

make the harness a lot more reliable You've probably seen me using the edge

of painters tape as a reference line, it gives me more contrast on very

dark woods like walnut or wenge by the way, I know it's pronounced wenJJe, even

in French, but wenGGe sounds much more funky WenGééé I also like to use painter's

tape in combination with CA glue to hold my pieces down on the workbench without having the clamps getting in the way of

the plane or whatever I'm using at the moment.

You can also use double-sided carpet tape. Aluminum or copper foil would

be used to shield the cavities, but you can also use conductive painting. You'll need some 80 120 and 240 grit sandpaper. For the fretwork, you're going to need

some 320 and 400 grit metal sandpaper I use regular PVA glue for all of my builds, and I know it's a debatable choice You could choose Titebond 2 or hide glue, but

those aren't easily available where I live You can use spray glue or a glue stick to attach the templates to the body

neck and fretboard blanks I've mentioned my use of CA glue before, and

it can also be used to glue the frets in place Fret cutters are luthier specialty tools designed to cut fret ends flush with the fretboard I've never had one but instead i bought a cable

cutter and filed off the upper part of the jaws to mimic those of a fret cutter.

It may not look sexy but in the

end it does the job and costs the third of a price of a dedicated fret cutter. A radius sanding block is a

block usually made out of wood, it has a concave bottom that matches

the arc across the width of the breadboard, which is known as "the radius". By sticking some sandpaper under

it and sanding your blank for hours you will eventually create that fretboard radius. This is by far the most tedious and least

pleasant part of making a guitar by hand. I've wrapped my head around this one for a long

time and I couldn't figure any alternative, so you will need to buy one. I did build one for myself but this is out

of the scope of this tutorial.

Mine has a 9.5 inch radius

but the choice is up to you. The higher the number the flatter the

curve. Vintage Fender's are usually 9.5", Gibson's are usually 12", but you can find anything between 7 and 18 inches. It doesn't change anything construction wise. You can also make the radius

with the router and a radius jig but again that would take too long to explain You will need some kind of "fret leveling beam", you can buy them online but I made my own by

sanding a piece of square aluminum tubing on a flat tile using metal sandpaper. It took

me about an hour to make it perfectly flat A miter box makes cutting

the fret slots a lot easier because it ensures that your slots

are square to the main axis of the fretboard I made my first guitar without one and I could really tell a difference

after I decided to build one.

You don't need to build one

from scratch like I did : just go to the local big

box store and get one there. Then, use your own saw to cut a

second groove square to the fence so it matches the curve of your saw blade exactly. As you can see mine has three grooves

one for each type of saw that I use This one is optional but it will

certainly make your life easier. The curve of the saw is designed to make the

fret tangs fit nicely inside the fret slots, without having to force them in and

risking some damage on the fretboard. I put this one in the optionals

because I've somehow managed to build five instruments without one, but that's only because by

chance one of my Japanese saws has a curve that is very close to 0,54 mm you can buy them if you want but those are very

optional I only started buying them one at a time when I slowly realized that guitar making

was apparently becoming a thing in my life, and that was after about five guitars Here are three power tools that can really make the process a lot faster

and less frustrating for you First one is the router and it's the

amateur guitar builder's best friend you can use it to shape the entire body

contour as well as the neck and headstock, to route out the pickup cavities, the control

cavity, the neck pocket, the truss rod channel, the binding channel,

and the fretboard radius.

And that's about 80% of what making a guitar is : "Removing wood from where it's not supposed to be" Any router will do, as long as it can plunge cut. In addition to the router you're

gonna have to get three different bits You'll need a flush trim bit, a template

routing bit, and a 6.35 mm straight bit The router also has some downsides, it's

a dangerous tool it's also very loud it makes an unholy amount of dust and the router bits always end up

costing more than the router itself. And finally, no, a Dremel won't work

because it's just not powerful enough A band saw or jigsaw can also speed up the

process of cutting the body and neck contours You don't need a big bandsaw like i do because making a guitar is not

very demanding for a bandsaw Finally if you don't want to spend hours and hours making the body side square to

the top and bottom with the rasp, or if you want to remove the marks left

by the bandsaw the jigsaw or the router, then get an oscillating spindle sander.

This is the list of all the

hardware and electronics that you're gonna have to get for this build It's basically what you get

when you buy a kit guitar except here you get to

choose exactly what you want. I will put links in the description

to the exact items that I used You will need fret wires the

size is up to you. But for a first build i would recommend

pre-bent and pre-cut frets. You will need a 43 mm nut. I

use pre-slotted nuts and i'm sure I would benefit from making

my own nuts using bone material, but I haven't had the time

to learn how to do that yet You will need a double action truss rod The one I used is 440 mm and will be adjusted on

the heel side of the neck with the hex key.

You'll need a tele bridge, a tele

pickguard, a control cavity steel plate, six string ferrules, one string tree, two knobs an d a switch. A jack plate, an output jack socket, two strap buttons, push cloth wires, two

pots, one capacitor, and a three-way switch, and of course you're going to need

a neck pickup and a bridge pickup, you can choose humbuckers or

p90 but i chose single coils. Just make sure that the pickguard is appropriate

and don't worry about the pickup cavity size Traditionally the body of a

tele is made out of ash or alder The neck is usually maple and the

fretboard can be maple or rosewood, that being said you can really pick any wood

species you want as long as it's hardwood, as opposed to soft wood. Even though the body of the esquire prototype back

in 1949 was made out of pine.

Here's what you should consider

when deciding which wood to buy You've probably heard of tone woods,

they are wood varieties that are said to have specific sonic properties

varying from one species to the other. For example, mahogany and rosewood

are expected to sound warm, whereas maple walnut and wenge

are said to sound much brighter The weight of the wood should also be a concern

especially if you have a shoulder or back problem in that case try to use lighter

species like basswood or alder, and generally speaking try to avoid a neck dive by balancing the weight of the

neck and the weight of the body Not all woods are equal when it

comes to sawing chiseling and planing some woods are very easy to work

with like walnut ash and maple they have a medium density and

are quite predictable woods meaning that when I put my chisel in,

I know exactly what's going to happen I would suggest those woods

for beginners especially walnut Other woods are very hard to work with

either because they're rock hard like wenge or because they have a grain pattern that is

constantly changing, like sapele or ebony.

Those woods aren't forgiving when you

don't know exactly what you're doing I get all my rifts on wood from a

general wood store here in Brussels They sell woods to companies making staircases, decking, roofs and all those

kinds of wooden things. In no way do they specialize in luthier

woods, but lucky for me the vast majority of the woods they sell happen to be

suitable for instrument building.

They range from domestic

woods like ash walnut maple to more exotic woods like

mahogany, sapele, bubinga or wenge. If you don't have such a wood store

near you everything's not lost. I'll try to find links to some web shops out

there and you should also check out ebay. For this project I chose ash for the body because

I wanted a very specific look with the finish on I used mahogany for the neck because by chance I had a perfectly quarter-sawn

piece left from my previous builds and I used rosewood for the fretboard because I never tried it before and when i built my shelf guitar, I didn't know

if I'd use ebony or rosewood, so I bought both Here's a quick list of the most commonly

used species for each component of the guitar and remember that this is electric

guitars we're talking about.

What i mean by that is when it comes to the sound, there are too many variables in play

just to narrow it down to the word choice In the end, you get to choose

whatever wood you want, depending on your tastes budget

and experience with hardwood Just google "Telecaster plan PDF" and

there's a ton of free plans out there I'll leave a link in the

description for the plans I used. The plans may seem overwhelming

at first but not all measurements mentioned in there are relevant

to what we're trying to do here As i mentioned previously the

telecaster is a very very simple guitar and we're now going to take a look at the

plan to illustrate what I meant by that.

Somebody once said in my comment

section that making a guitar is easy: it's just gluing woods together and then

taking out everything that's not a guitar Well he or she wasn't

wrong, especially for a tele build. The body is literally two pieces

of wood glued together and then cut so the whole thing vaguely looks like a guitar There's no complex carving on the top,

nor in the back, there's no comfort, cut no belly cut there's no complex

routing to get the electronics in, there's no back plate, no mortise for a set

neck no neck to body transition, no neck angle. It's just a stupid block of

wood with holes here and there The neck is also very simple You see, most guitars have their headstock angled towards the back to put some downward

pressure on the strings at the nut. Such an angle is obtained by cutting the headstock angle that way or by making

what is called a scarf joint and while it is not very hard to do at all,

it's still some more work and adds a tiny bit of complexity to your first build

Well there is no such thing on a tele, as the headstock is simply on the plane

that's parallel to the plane of the neck You don't have to worry about any angle, at all.

Also the bottom of the heel and the bottom

of the headstock are perfectly aligned, which will also make your life easier

when you're trying to clamp things. Now about the plan and what to do with it. You will need to print the

three templates separately. We'll glue them on the body

neck and fretboard blanks. Just print out any file you want

because we only need the contour lines, the fret and nut positions, and the center lines. Those are the three elements that

we're actually going to print out, because we're going to mark the rest

of the measurement on the actual wood. I couldn't find a file with just a

fretboard on so just print the neck template twice and then isolate

the fretboard on the second time Also make sure that the printer is calibrated

so it actually prints on the one-to-one scale This is especially crucial for the fret positions

if you want your guitar to play in tune, and also make sure that the center lines are

perfectly straight on the three templates because we're heavily going to

rely on them for the whole build If you can do it try to find the

printer that handles A3 sheets, because if you rotate the neck by 33°, the fretboard will sit nicely

inside one page diagonally, no need for complex glue up and

you'll gain a lot of precision by doing so.

We'll use the center line as a reference

and not the size of the fretboard so don't worry if you don't cut straight If you have the tools to do the milling

by yourself at home, that is a planer or jointer and a table saw or if you know how

to do it by hand, here are the dimensions. If you don't then just download the

cut list in the description box below and ask the good people from the lumber

yard to dimension the wood for you. It's not worth investing in heavy machinery or

learning how to do it by hand at this point. Just pay a little extra to

the lumber yard and you'll have everything you'll need for your first guitar.

A few very important things

are worth mentioning here, if you don't want to run into troubles later. You can make the entire

body with just one piece of wood but larger and good quality pieces are

pricier and they are harder to find too. Compared to just cutting a board

into and gluing the pieces together this last option also makes

the body blank more stable as it won't warp as easily as a one piece body also if you use two pieces

you can sort of bookmatch them The thicknesses have to be absolutely

spot-on and consistent across the board. That's 45 mm for the body blank. 19 mm for the neck blank that is 3/4 inch or 9/15 of a potato and 6.35 mm for the fretboard or 1/4 inch or two bananas I counted 100 mm of extra length on each board because most of the planers,

even professional ones, will leave some kind of snipe at both ends, sometimes it's very subtle but it's there. And you

don't want your neck to wobble in the neck pocket or your body to have a sudden

dip next to your strap button.

If you're confident that you won't have a

snipe then you can subtract those 100 mm. My snipes usually happen at 50 mm from the ends. If you have no idea what i'm talking about then

just trust me and get those 100 mm extra. Make sure that the milling process got

rid of any twist bow or cup in your boards You can check that by putting your boards flat on the workbench and then

pressing on the four corners … … if your board moves even the slightest then

it still has a defect and you need to address it You need to have all the edges of

the boards of your body blank jointed which means that their edges are

perfectly square to their faces in fact, two would be enough but if you

have four of them then you'll be able to play around with the wood figuring

and try out every possible combination as for the neck blank you don't need to have

any square edge because we'll cut them anyway It's easier to have one good edge on the fretboard blank because we're gonna use

it as a reference the miter box About grain orientation Quarter-sawn is arguably the

best choice because the wood will be more stable through seasonal changes and that is especially true for neck and fretboard but for a first build I wouldn't

care about that too much If you can't get your hands on quarter-sawn or rift-sawn wood, or if you don't have

any idea of what I'm talking about just buy anything pretty hard and

well dried and you'll be just fine my body blank on this guitar is flat

sawn and I'm pretty okay with it Oh and try to avoid knots or have them

where you know they won't cause a problem I will conclude this first part

by sharing a few thoughts so you have a better idea of what

making a guitar at home will involve I have a workshop at the back of my garage but I

haven't always had such a dedicated space For a first time build with

a restricted number of tools, the only thing you're gonna

need is some kind of workbench and any kind of table will work as

long as you can clamp things on it but it also has to be stable enough meaning that

it won't fall apart when you strike your chisel in Also the whole thing will produce a lot of sawdust so maybe don't do it in the

kitchen or in your kid's bedroom On average it usually takes me about

four to six weeks to finish a guitar project but i'm pathologically slow and since this is a hobby and one

that's supposed to be relaxing at that I never feel any rush So building a guitar at home is time consuming but so is a thousand piece puzzle

or stamp collecting or bird watching I'd rather make guitars though because

I'm not smart enough for puzzles and I'm genuinely afraid of birds The budget depends on where

you decide to spend your money but generally speaking the thing that is going to make all the difference is the

hardware and the electronics Most of the time they will cost you

more than all the tools combined Just like with bird watching, experience will help

but if you've never done any woodworking before it's not a big deal.

Building a guitar

like a telly is not as hard as it seems As I've said over and over there's

gonna be a lot of room for mistakes I'll try to make a foolproof tutorial and

will tell you when to be extra careful Also I'm probably going to upload a short video

explaining you how to actually use the tools as well as some tips and tricks for the main

ones, that is the saw the chisel and the plane I'll see you for the next video, it's gonna be

the actual step-by-step tutorial to the build I'm gonna take you to the workshop and I'm

actually gonna show you what to do and remember I did it with one hand so you can probably do

it with two you don't have any excuse anymore.