This is the first video i n a five-part series

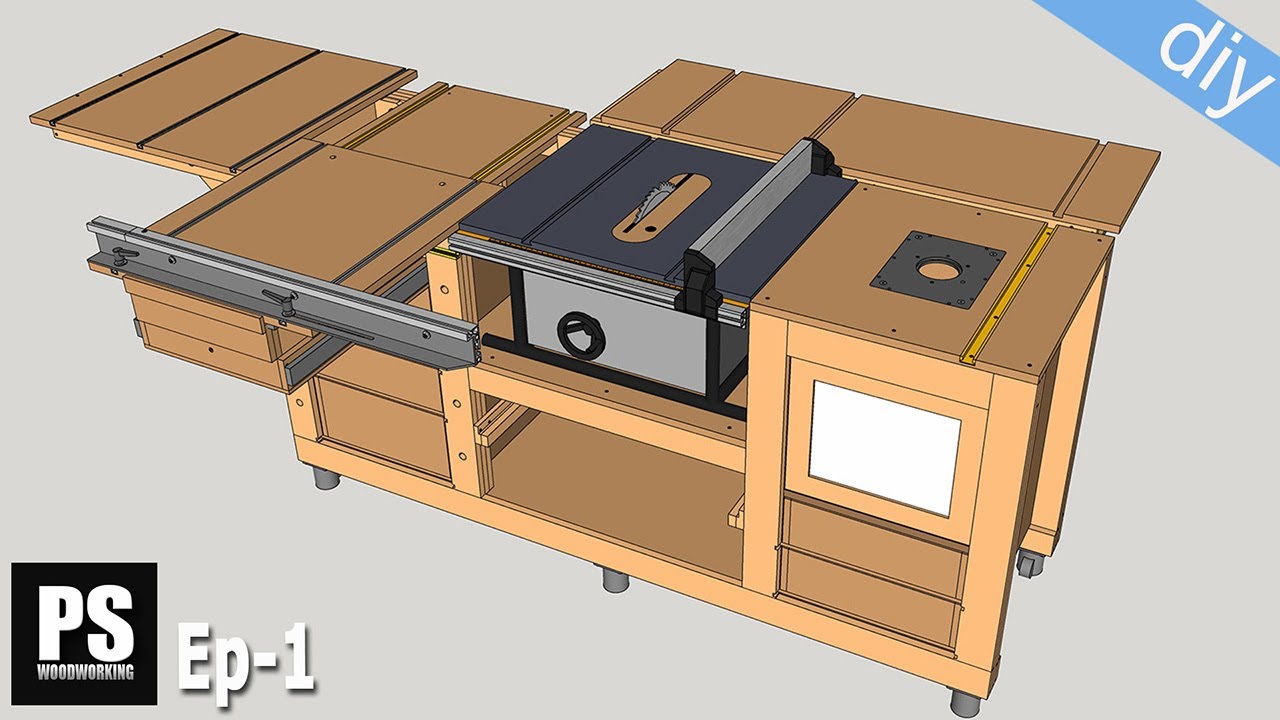

where I'll show you how to build a robust and versatile woodworking bench to which I'll

also attach my new bench table saw and a router table. This is the 3D SketchUp file included in the

plans, available on my website. As you can see in the animation, I'm going

to install two folding tables to save space when I'm not using my bench, as well as to

have more space to work when necessary. I'll also make a sliding carriage for more

ac-curate and comfortable crosscuts. I'll start off by showing you how to build

the frame. First, we'll make the four outer legs. I've cut a piece of wood, which I'll use to

space the pieces evenly.

I apply glue on the wood and use nails to

secure the pieces. I clamp two legs at a time. Don't forget the legs must be symmetrical. Now I'll move onto the four inner legs. I follow the same steps as when I built the

outer legs to make tenons and mortises, but these are a little different. In order to make the assembly process easier,

I ordered cut-to-size frame pieces and cabinets in the same place where I bought the board. If you want to do this project and you already

have a bench saw, you can cut them yourself at home. Now, in much the same way, I'll make two mid

rails. They're a little bit easier. Next, I'll make the two top rails on the right

side, where the router will go.

As you may have noticed, from the beginning

I've been marking the spots where I'll put glue on the pieces. Now, I'll make the top rail for the left side,

where I'll place the sliding carriage. And now, the back rail. These two are a little different. Lastly, I'll make two long bottom rails. First I'll make sure all the pieces are the

right size. I'm going to need a few clamps to apply pressure

evenly.

I'll run some tests to see how good the mortise

and tenon joints are, and they seem to be perfect. With a hand plane, I correct the inner rebate

of some of the legs which needed it. In order to assemble the frame, I need to

drill some holes in the legs. Some 20mm diameter holes for the holdfast

clamps. And some more holes for the folding table

axis on the left side. Now I can start putting together the parts

that make up the frame. I'll do this bit by bit, joining one of the

long bottom rails with the two legs and the short top rail. I put low pressure on the clamps, and finish tightening them little by little once they're

all in place and after making sure they're square. Once the glue is dry, I turn the frame to

glue the mid rail on. First I drill some holes for some dowels that

will strengthen the bond. I'll sand down the inner side of the frame,

now that it's more convenient.

Now onto the inner cabinets. First of all, I'll make sure the pieces are

proper size by inserting them into the frame rebates. With the table saw, in several runs, I make

channels for the drawers to slide on. I'll definitely need a dado blade for these

cuts. In the SketchUp design, I joined the cabinets

with screws. This works fine, but in my case, I'll use

some biscuits. I apply glue and clamp them together. Now I'll follow the same steps with the router

cabinet. In the cabinet, the top piece is lower, at

medium height, more or less.

Before putting this cabinet together, I cut

a notch on the outer side so that I can later add a power switch. And now comes my favorite part–joining the

modules with the frames. Before using glue, I make sure the cabinets

fit into the rebates. I apply glue, insert the cabinet and put pressure

with clamps. I follow the same steps with the second module. Once the glue is dry, I can glue the second

frame part on. This time I have to glue on two modules at

the same time. I'll need all my clamps for this step. Before moving on, I'll fasten these small

pieces with glue until that part is thick enough to later attach the wheels with screws.

I'll also glue another a piece like this one

in the middle of the bottom of the frame. Once the glue is dry, I smooth down all the

frame joints with a hand plane. With a saw and a chisel, I make channels for

the drawers in the front of the frame. Once I'm done, I'll screw the wheels to the

bench, I only have four wheels in the shop. I'll add the two middle ones later on if necessary. and also some metal plates to reinforce the bottom shelf. I turn the bench and check how firm and stout

it's going to be! Now I make some recesses to the central

shelf, where I will be placing the bench table saw. I make sure everything's as it should be and

see if I can use the saw fence. Now is also a good time to finish the electrical

installation. It's quite simple. I'll use a power strip and an emergency paddle

switch. I fasten a junction box with screws to protect

the back of the switch, as well as an outlet for the router.

After screwing a power strip to the bench

and checking al the connections, I make sure everything's working correctly. That's all for today. In a few days I'll upload the second video, where I'll be showing you how to make a sliding carriage..