let's have a look at using a CNC router

to make wooden signs mill brass cut cardboard templates machine

polycarbonate and grave granite and cut builders phone before getting started be

sure to check the RPM of your spindle or router in some cases the RPM is zero

you'll also need to check the feed rate the travel of the spindle a router to

make sure it's right check your owner's manual for how to do this with your

machine and have a look at the companion article that goes with this video for

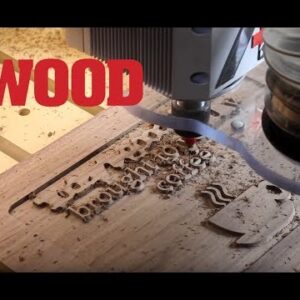

specifics on feeds and speeds first let's look at cutting letters and a

design into this walnut board the work is being done with a 60 degree half-inch

V bit one of the things that's interesting you'll see in our next

project we're going to use the same design twice with slightly different

tool pads to get a different look with the lettering and artwork done I'm now

using a quarter inch bit in order to cut the final shape on the outside of our

sign and here's a result same design but

different look coming at you here in this case the letters will be raised

from the background so we're starting with a quarter inch bit and that's

eliminating a lot of the background waste here as you're choosing the cutter

for this operation keep in mind that a large diameter bit will remove the waste

more quickly but a small diameter bit like this quarter inch is better able to

get into the detailed spots artwork like this ends now we're back to that sixty

degree half inch B bit and this bit is gonna cut in all the details look how it

leaves those letters stand proud of the background giving this sign a very

hand-carved look I have made a lot of projects with this technique but I still

find it very intriguing to watch how the CNC machine controls the bit and allows

it to create these very fine details now we're back to that quarter-inch cutter

again in order to cut the final shape and dimensions of this sign just like we

did on the last one when you see the spindle lift slightly it's leaving tabs

behind bridges that connect the work to the surrounding frame that hold it in

place same artwork different tool path in a different look the brass is being

milled with a single flute eighth inch diameter cutter making a bowtie that

I'll put into a walnut table non-ferrous metals require a very light depth of cut

and notice here I'm finishing up with a client cut in order to get the best

possible surface finish on the brass double-faced tape works great for

keeping the brass secure to a waste board and I can't wait to get this

project done when you're using a drag knife like we are here set the spindle

or router to zero rpm zero rpm let me repeat at zero rpm you don't run the

spindle the router for this operation what a great way to turn your project

plans into templates that you can use in your shot it's amazing how the drag

knife will pivot as it's pulled through the material in order to cut pretty

complex shapes I clamp a melamine backer board to the CNC table and then you

spray adhesive on top of the melamine to keep the cardboard secure and these

parts are ready to trace onto your project pieces

the quarter-inch polycarbonate is being cut with a quarter inch single flute

that and if you watch carefully here you'll notice that the image has been

reversed and is being cut into what will be the backside of the polycarbonate

this is a pretty common approach to see-through materials this is a good

time to mention to the dust collection on the CNC machines is great when the

dust shroud is on but in order to shoot video I've got the dust shroud removed

with double-faced tape holding the polycarbonate in place I'm cutting

completely theer on this pass no tabs to produce the final outside shape and what

would recur doesn't need this in their shot here's another case where you'll

set the spindle a router rpm to zero you don't spin it for this this is a diamond

drag there is literally a piece of diamond in the tip of this tool when you

set depth of cut on the diamond drag what you're doing is controlling how

hard the spindle pushes down on the compression spring in the tip harder

materials require more down pressure it's all very well explained in the

instructions that come with the tool this work can be done on granite glass

aluminum brass steel lots of different materials I love the look

yep that's a piece of standard pink building foam right off the shelf at a

home center because it's two inches thick this provides a great way to test

your cuts in a relatively inexpensive material before you throw a really

expensive slab of wood onto your CNC or you can use it for what I'm doing here

and create 3d artwork the roughing out portion of the cutting is being done

with a half-inch and mill that'll get most of the waste removed the detail

work is being done with a half-inch round nose bit that works here because

the artwork is pretty good-sized if you're working on a smaller piece in

order to get all your details probably have to go to a smaller diameter cutter the final outside shape is being cut

with a half-inch and mill saying that we did the roughing pass with again I'll

leave tabs behind to bridge the workpiece to the frame a little bit of

latex paint and we're good to go like driving your car speed limits

aren't just to suggest you in there the law when you're running your CNC router

you've got to pay attention to feeds and speeds to get everything to come out

right