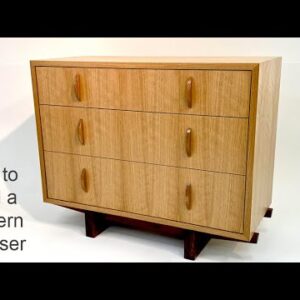

i just finished building this modern dresser it's

made with quarter saw and white oak veneer it has soft clothes under mount drawer slides and it

sits on a solid walnut base i'm really happy with the way it turned out and in this step-by-step

video i'll show you everything you need to know to build this project this project is sponsored by

geoveneer click on the link in the description to visit the geoveneer gallery and see a wide variety

of veneers to choose from for your next project and mohawk finishing products i've been using

mohawk finishing products for more than 30 years from sandpaper to fill sticks mohawk has

all your finishing needs this cabinet is basically a box made of three-quarter inch

plywood that will sit on a solid walnut base i'll get started by rough cutting the parts

of the box to size using my circular saw once the pieces are smaller and easier to handle

i'll use the table saw to rip them to width then i'll use the miter saw to

cut the parts to a rough length now i can set up a stop block at the crosscut

sled and cut the parts to their final measurements with the parts for the back and the sides

cut i'll pre-drill and countersink holes to attach the sides to the back

i'll measure in 3 8 of an inch and draw a line and then measure

down two inches and 10 inches on each side i'm attaching the sides of the cabinet from

the back this is to avoid seeing the edge of the plywood at the back of the cabinet i'll fill

the countersink holes later with wooden plugs making sure that the sides are

clamped in position and flush i'll drill pilot holes before using inch and

three quarter cabinet screws to attach the sides now that i have the sides attached to the

cabinet i'll take an inside measurement at the back and it looks like it's 38 and 9 16

and i'll cut the top and bottom to length with the top and bottom of the cabinet

cut to size i'll clamp them in position and attach them to the cabinet using wood

glue and inch and three quarter cabinet screws screwing through the back and sides of the cabinet i've run into a little bit of an issue the

back of the cabinet is nice and square but the front of the cabinet is about a

heavy eighth of an inch out of square i'm pulling it square now with this clamp

and i've tested it with the framing square and the way i'm going to deal with this is to

add a four inch bracket set in about two inches at each corner i had a few of these four inch

brackets some of them were square some of them weren't so i've tested them just to make sure i've

got four good ones here and i'm going to go ahead and set these in and hopefully that will take care

of the problem the drill bit i'm using here is a self-centering drill bit also known as a vix bit

these are great for drilling small pilot holes in metal hardware with the brackets clamped in

position and the pilot holes drilled i'll screw them in place if your cabinet is square you can

skip this step but if not this option did work the next step was to fill the countersink holes

in the back of the cabinet with wooden plugs after allowing the glue to dry i trimmed the

plugs flush with a straight bit in the router i'm ripping quarter inch baltic birch plywood

at an inch and 7 8 to beef up the front of the cabinet to a full inch i'll also add this material

at the back and sides of the cabinet and that will make sense when i attach the drawer slides just

a quick note quarter inch baltic birch plywood is thicker than most quarter inch plywood commonly

available at your home store or lumber yard more commonly available quarter inch

plywood actually measures closer to 3 16 where quarter inch baltic birch plywood

measures just about a full quarter of an inch after applying the quarter inch plywood

to the front and back of the cabinet i'll also apply quarter inch plywood

to the sides of the cabinet where the drawer slides will be attached i'm

referring to these parts as blocking now that i've finished with the blocking on

the inside of the cabinet for the drawer slides the next step is to band the edge of the plywood

with cortisone white oak i'll use the table saw to rip the white oak edge banding three quarters of

an inch by one inch a little heavy then i'll run the molding through the drum sander to remove

the blade marks and sand the edge banding to the same thickness as the plywood cabinet with

the sacrificial fence set up on my miter saw i'll trim the front of the cabinet attaching

the molding with inch and a quarter pin nails before you start your next project

visit my website and check out my professional woodworking plans the detailed

instructions along with materialist and free video tutorials on youtube will help you

build a project that will last a lifetime with the edge banding attached the next step is

to make the drawers i'm making the drawers with 5 8 baltic birch plywood baltic birch plywood is

great for making drawers because it's very dense and has very few voids on the downside baltic

birch plywood is prone to tear out and splintering here i'm using a zero clearance fence set

on top of my miter saw to help prevent that after rough cutting the parts

to size and squaring up one side i'll set up a stop block and cut

all the parts to their final length now i have the drawer fronts backs and sides

cut to size the next step is to cut a groove for the drawer bottom i'll use a test piece cut

one pass on the test piece and all of the parts then i'll adjust the fence until i have a good fit

with the material that i'm using for the drawer bottom once i've got a good fit in the test piece

i'll make the second pass on all the drawer parts with the fence set at a half

inch and the blade height set at a quarter of an inch i'll make one

pass on the test piece and all of the parts because you need a half inch lip at the bottom of

the drawer when using under mount drawer slides i'll move the fence to the

right to cut the second pass once i've got a good fit on the test piece

i'll make a second pass on all the drawer parts after cutting the groove in all of the drawer

parts i'll keep the fence right where it is raise the blade and run the back of the

drawer through the saw one more time cutting off this lip so i can

drop the drawer bottom in place if you're thinking that it was unnecessary to cut

the grooves in the drawer backs in the first place you would be right but with so many parts

it's really easy to get confused and this method just works for me the drawer bottoms

i'm using quarter inch baltic birch plywood and i'll rough cut the bottoms to

size before assembling the drawers i'm going to build the drawers by simply screwing

them together with inch and a half cabinet screws the first step is to measure and mark to

pre-drill and countersink evenly spaced holes for the screws like i said earlier baltic birch

plywood splinters easily so i'm taking my time and drilling the holes slowly to avoid tear out when

i build the drawers i'll use wood glue and tack the parts in position with an inch and a quarter

pin nail just to keep them from moving around then i'll use an inch and a half

cabinet screw for the stronger joint because baltic birch plywood is so

much more dense than normal plywood i'm pre-drilling pilot holes to avoid splitting

the plywood or possibly breaking a screw now that i have the drawers assembled

i'll take a measurement from the back and cut the drawer bottoms to size now i can drop the drawer bottom in place

make sure it goes into the groove at the front and chase a line at the back now i'll rip the drawer bottom at the line so

the drawer bottom is flush with the drawer back i'll add a bead of glue to the groove in the

drawer front and then drop the drawer bottom in place and attach the drawer bottom

to the drawer back with one inch screws with the drawers finished next i'll

get to work on the drawer slides i'll place the left drawer slide

on the bottom of the drawer and tap it at the back so

the location pin makes a mark i'll then use an awl to make

that mark a little deeper next i'll drill a 13 64 hole to accept the

location pin at the back of the drawer slide then i'll repeat this process on the other side

of the drawer and drill a quarter inch hole i posted a detailed video on how to install

under mount drawer slides a few weeks ago and i'll have a link to that

video in the description below now i can attach the undermount drawer

clips at the front of the drawer to help align the drawer slides

perfectly straight with the cabinet i'm using a piece of scrap plywood cut at 19

inches and i'll attach the top drawer slides first to attach the middle drawer slides i'm

using a piece of scrap plywood cut at 10 inches so the bottom drawer slides are

attached at the bottom of the cabinet okay now is looking pretty good now theoretically

you could fit the drawers after you finish the entire cabinet but since i'm still kind of

getting used to the undermount drawer slides and i'm designing this piece as i go i

thought i would fit the drawers first now that that's done i'll make the drawer fronts i'm making the drawer fronts out of three

quarter inch baltic birch plywood and i'll get started by cutting them a half inch light to

allow for the quarter inch white oak edge banding i'll rip the white oak edge banding one

quarter by three quarters a little heavy and then i'll run the molding through

the sander to remove the blade marks and bring them down to the same

thickness as the drawer fronts with the sacrificial fence back

on my miter saw i'll attach the edge banding with wood glue and one-inch pin nails so before i move on to the next big step of the

project i'll fill the countersink holes in the drawers with walnut plugs i'm using ca glue

here because it sets up really fast after tapping the plugs in place i'll spray them with a little

activator and then trim them flush with the router okay well now i'm really starting to make some

progress i've got the cabinet built the drawers are built the drawer fronts are made and the

next step is to make the base of the cabinet and i'm making that out of solid walnut i want to

have a gradual arc at the bottom of the base and to do that i'll need to make a pattern to make the

pattern i'm using a piece of quarter inch plywood that measures three inches i happen to have

this in the shop you could also use half inch or really whatever you happen to have

and i'm using a piece of poplar that measures three-eighths by three quarters and that

will allow me to get that nice gradual bend i'll make the pattern and then i'll

use the pattern to create that same arc in the base the poplar stick measures 44.5

inches and i'll measure from each side at 2 10 and 20 and a half inches and i'll

mark to drill holes in the center i've measured down from the top of the pattern

and made a mark at an inch and three quarters and i'll move the stick to

that mark and clamp it in place and then use a one inch screw to screw it down

and then use another screw at the 10 inch mark now i can use the band saw to cut along the

guide a little heavy leaving some of the material next i'll use a flush cut bit in

the router to make the pattern with the pattern made i'll mill the

walnut material for the base to size i'm making the stretchers for the

base out of five quarter walnut and i'll get started by

ripping them at three inches for the feet of the base i've laminated

two pieces of five quarter walnut together and plate them down to one and

three quarters after running them through the jointer i can

rip them to size at six inches after squaring up one side i'll set up

a stop block and cut the parts to length i'm building the base of the cabinet out of solid

walnut and i'm building the base with lap joints i've measured and marked to have 18 inches

between the feet and i've set up a stop block and i'll make that first cut on both sides of each

piece when i cut the lap joint in the stretchers i'll also cut a lap joint on a piece of

scrap wood so i can sneak up on the cut and test the fit before making

the cut on the work piece with a good fit on the scrap piece i'll make

the cut on the work piece and then plow out the material in between the cuts the long boards

that make up the top of the base i'm calling them the stretchers and i want the stretchers set

in two inches on each side of the foot so again i've set up a stop block at two inches and i'll

make that first cut on both sides of each board after making the first cut

on both sides of each piece once again i'll make sure to get a good fit

with the scrap piece before making the second cut on the work piece and then plowing out the

material between them to make the lap joint with the lap joints finished i'll

trace the pattern onto the stretchers and cut them out on the bandsaw a little

heavy making sure to leave the line now i'll set the stretcher on top of

the pattern keeping it flush at the back and holding it a half of an inch

from the edge of the pattern on each side i'll clamp the work piece to the

pattern and add a bead of hot glue at each end to make sure the parts stay in position

while using the flush cut bit in the router so the stretchers will travel three

quarters of an inch beyond the cabinet and to give it a little bit more of an

interesting shape like this one here i'm using a quarter i'll hold it flush

and centered and trace it with a sharpie and then i'll use a hand

plane to shape to the lines and i'll use a pencil to draw a mark in the

center and use that as a reference point for an added design element i'll use the miter saw to cut a 5 degree angle

at the end of each stretcher next i'll use the drill press to drill a pilot

hole in the center of each lap joint in the stretchers then i'll countersink the holes so

the screws are below the surface of the wood when the base is assembled using

a round over bit in the router i'll soften the edge at the

bottom and front of the foot before i assemble the base i'll

drill pocket holes in the stretchers so i can attach the base to the

cabinet with pocket hole screws to assemble the base i'm using

wood glue and two inch screws and i'll make sure to clean up the glue

squeeze out with a wet rag before it sets up okay well now i'm ready for the fun part which is

applying the veneer i've got my drawer fronts on top of the veneer just to kind of get a good

idea of where i want to make that first cut i want the grain to run up the front of the

drawers so i'll make my first cut here and that's going to leave me with this to veneer

the cabinet now theoretically it would be good to have two sheets of veneer because to get

that waterfall effect it would be very easy if i had another sheet just to measure in about

18 inches make the cut and then i'll be able to wrap the cabinet the grain is pretty consistent

though so i think i should get a good grain match anyway it's not going to be perfect but it's going

to be pretty close but if you are going to build this project maybe consider getting two sheets and

then just using the offcuts for another project i've measured up 27 and a half inches

and i'll make my first cross cut the next cut is with the grain making sure the

measurement is at least a half of an inch heavier than the drawer fronts are wide with the drawer

fronts labeled i'll crosscut them to size next i'll cut the veneer for the

left side and top of the cabinet i've got the left side of

the cabinet cut and labeled that will run into this grain which is the top and

now i'm using the top to find the best grain match for the right side of the cabinet and

that looks pretty good just about there to glue the veneer down i'm

using weld wood contact cement the first coat seems to really absorb into

the material so i like to use two coats allowing the first coat to dry

before applying the second coat when the second coat is dry

to touch i'll use sticks laid across the surface of the drawer

fronts to help position the veneer once the veneer is in position

i'll remove the sticks and apply even pressure working from one side to the other on the drawer fronts i'll use a j-roller to

apply pressure to the veneer to get a good bond make sure to be careful near the edges because

you don't want to accidentally break the veneer the next step is to use a flush cut

bit in the router to trim the overhang i'll repeat the process to

veneer the cabinet veneering the sides of the cabinet first and then the top because the cabinet is a larger surface than the

drawer fronts and i can work in the direction of the grain i'm using a board to apply pressure to

the veneer to create a good bond the board is a piece of three-quarter inch plywood with a round

over at the edge so it doesn't scratch the veneer and this is my preferred method

of applying pressure to the veneer but the drawer fronts were too small to be

able to work in the direction of the grain after trimming the veneer with a

flush cut bit in the router i'll use a sanding block to carefully sand away

any glue residue that might be left behind for the finish i'll use three coats of

mohawk's finisher's choice clear lacquer sanding in between coats with 320 sandpaper once the finish is dried i'll attach the

base and reinstall the drawer hardware to make the drawer pulls i'll use a paint

can to make a pattern on half inch mdf with the pattern made i'll rip a piece

of white oak with an 8 degree angle then i'll trace the pattern and cut the drawer

pulls out on the bandsaw clamping two pulls together with squeeze clamps will make them

easier to sand and shape on the belt sander i'm using a piece of eighth inch masonite as a jig and i'll mark with an awl where i'll

need to drill holes for the drawer pulls i've got an eighth inch spacer

holding the drawer front in position and i'll attach the drawer from to the

drawer through the hole for the drawer poles with the drawer front in position i can now

attach it through the holes that i drilled earlier with the drawer pulls clamped

in place i'll pre-drill holes into the poles and attach them with

two inch and three-quarter screws well i am really happy with the way this

project turned out and if you want to build it there are professional plans available

on my website and i'll have a link to them in the description below as always thanks

for tuning in and i'll see you next time