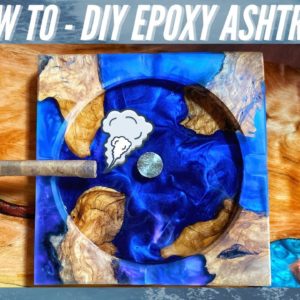

– [Narrator] And we're back. You ready to pour another one? Let's get after it. This is gonna be a cigar ash tray. I've made a bunch of these in the past and they've done really, really well. They're really, really cool. And wait 'til you see the end product. We're getting our Upstart

Deep Pour Epoxy poured up. We're gonna be using a

couple of familiar colors. They're so beautiful, and they go so well together. They are Pacific Blue

from MEYSPRING pigments, and Purple Sage from Eye Candy pigments. Take a look at that. Wait 'til we start mixing it. It's even better.

There's the blue. And let's go. Look at that, gorgeous, just gorgeous succulent color. Look at that beautiful purple. It's like almost a two-tone purple. It's just so cool. And voila, here's the beautiful pour. Look how well these

two colors go together. They just really really

complement each other and we love using them. So if you guys want to try them, those are the products. Peep them out. And of course, Upstart

Epoxy is awesome as well. Try them for sure. So here we are taking it out of the mold. I like to use HDPE for my molds. I make my own molds, and it's just so good of a product and you can use it over and over and over.

We'll be doing a video soon on the difference between like

wooden forms and HDPE forms and just kind of show you

guys how we make our forms. There's a lot of different

form ideas out there, and they're all really, really

good, and they all work. And the most important thing is you want a good solid structure because you want something beautiful to come out of that form. So we're done with that. Going ahead and taking off

those high points as usual with the band saw.

Now we're gonna plane it on

up, get it nice and flat. And now this is the fun part. I have a circular jig

router bit that I use. It's an attachment for your router and it cuts a perfect

circle out every time. It's kind of a long process, but it's so well worth it because it gives you a perfect circle. After I'm done with that, I'll pop off the middle knob out of there with a 80 grit flap disc. So there she is, she's looking good. This is just a preliminary sand. And now we'll cut out

the cigar rests on here. I like to do roughly like

a 34 gauge, a 48 gauge, a 40 gauge and then a 54 gauge

for them big gauge cigars. I'll use my grinder here just

to give me a little cutout, just a small little cutout to

give me something to work with so when I take it into

the standing center, I can go ahead and sand that out. A lot of people see this and

might think in an obscene way.

We're not gonna judge you. Anyways, let's get back to routing. We're gonna go with a

small chamfer edge on this. And I like to do the

bottom side and the top. Now we're gonna cut out the

centerpiece hole for our striker where the cigar smoker will use to extinguish his cigar or her cigar, sand it up to 800 grit. And I included a flame

retardant powder with our sealer so that the cigar smoker

won't burn the ashtray once they use it. But tip to everybody, always use your striker

to put out the cigars, not the bottom part. And here she is, folks. Shined up, gorgeous, beautiful as ever. (gentle music) If you follow us on Instagram and you're watching this video, leave a comment down below

so we can say what's up.

Always enjoy working with you people. Always enjoy showing everybody how we achieve these beautiful pieces. And most importantly, we want

to work together with you. So if you like this video,

hit that like button. If you really want to see more, hit that subscribe button. But most of all have a great day. And this was Foreman approved. (gentle music).